Rifleman: A gentleman farmer becomes a precision gunsmith

Published 12:00 am Friday, July 28, 2017

CLEVELAND — When he was 6 years old, Gary Blythe received a .22-caliber rifle from an uncle, who won the gun in a raffle.

Call it a raffle rifle.

Gary’s father, who was always keen about gun safety, stowed the gift away for a while and substituted a BB gun for his son. All this is background — a way to say Gary grew up with guns and knowing the proper ways to use and maintain them.

“I’m a nut on safety,” he says.

Today, Blythe is 66 and living in the far reaches of western Rowan County on a beautiful 150-acre farm with cattle and horses. The giant white gate leading into his farm off Chenault Road spells out “Blythe Bucking Bulls” over the drive.

Blythe used to receive a pretty penny for the bulls he raised here, but he’s slowly selling off his herd. Once he had 60 cows. Now he’s down to 30.

In January, Blythe’s 30-year company, Equipment Painting and Sales, shut down for good. At one time, he employed 27 people, doing contract work almost exclusively for the Colonial Pipeline.

In the end, he was a business casualty of the Colonial Pipeline explosion and fire in Alabama last year, as work suddenly stopped coming his way. Blythe paid off his six employees and closed down.

But Blythe had no intention of retiring. “I just like to stay busy,” he says. “My dad said if you love what you’re doing, you’ll never work a day in your life.”

In addition, “Social Security wasn’t near what I thought it would be,” Blythe says.

So Blythe has become a gunsmith, more accurately a precision gunsmith. He obtained his license — an expensive firearms manufacturing license because he can make gun parts — and established Accurate Rifle.

Blythe has converted a 15-by-30-foot corner of his farm shed into his new gunsmith’s shop, giving it a door and a soft tile floor. One of his mentors, Gordy Gritters, told him never to do his gun work over a concrete floor because you don’t want to drop someone’s cherished gun onto the concrete and see it break.

This part of the farm shed used to house a tractor — “the tractor got shoved aside,” Blythe says.

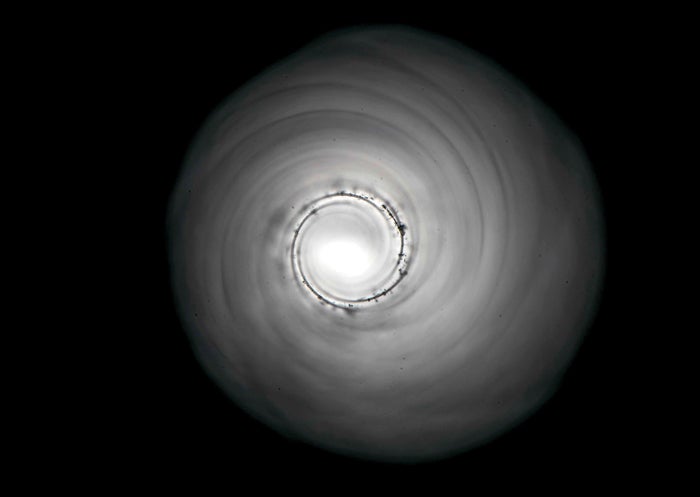

Blythe brought in the crucial equipment he needed, including a lathe and milling machine, and his work benches are filled with all manner of specialty tools, such as a reamer and fiber-optic bore scope, along with the more traditional implements such as files, pliers and wrenches.

“There are a lot of gunsmiths around,” Blythe says, “but not many do the precision work. And you can’t do the precision work without the right tools.”

Blythe specializes in “accurizing” and customizing long-range, tactical and hunting rifles, but he emphasizes, “I’ll work on any kind of firearm.”

“I love making a rifle that won’t shoot shoot really well. … My love is target rifles and hunting rifles.”

Because of the acreage he owns, Blythe has one of the rare places in the state where you can legally shoot a distance of 1,000 yards — almost three-quarters of a mile. And he is in the process of building a shooting range that he, his son-in-law and a few friends will be able to use.

“I must shoot every firearm I work on before I return it,” Blythe says.

Besides repairing and improving the accuracy of guns brought to him, Blythe also enjoys taking barrels, receivers or other parts from older guns and making everything else for, say, a new target gun.

Blythe knew a lot about guns to begin with and says you can’t go to college or watch videos online to be a gunsmith. “Until you’ve actually torn into a gun, it doesn’t mean a thing,” he says. “Experience is the only thing.”

But Blythe wanted to know more. In 2016, he traveled to Kansas City and took two weeks of training from Gritters, for whom he has the highest respect. “It’s a premium (cost) to go there,” Blythe says.

Every class in Extreme Accuracy Institute was limited to six students, each “hunting to get an edge, just like me,” Blythe says.

Blythe took instruction in things such as stocks, barrels, chambers, boring, lapping, scoping and diagnosis. He learned more about slugging barrels to find accuracy problems, pillar bedding techniques, scope mounting, stock stiffening and minimizing barrel vibrations and harmonics.

“He told you secrets no other gun builder would tell you,” Blythe says of Gritters. “… Little things you wouldn’t think about causes a gun not to shoot well.”

Blythe says the problems with a gun’s accuracy might have 100 different causes, and he’s like a doctor trying to find the solution. At the Kansas City institute, Blythe was like a sponge, soaking up all the things Gritters knew about high-accuracy rifle-building and accurizing techniques.

“When I went to that school out there, I didn’t want to leave,” he says.

In his shop, Blythe takes out an old Mauser he purchased himself and explains how he’ll use the gun’s receiver and add all the other components to make a new rifle.

He explains about the harmonics of a rifle. “The more the harmonics, the more the barrel shakes,” and the better the chance a bullet will go off its intended course.

Blythe’s Accurate Rifle has been in business about four months, and he relies on word of mouth to connect him with people needing his skills as a gunsmith. People can contact Blythe at gbrifles@gmail.com or by calling his office at 704-278-0003.

“I’m in here most every day when I’m not feeding the cows,” Blythe says.

Contact Mark Wineka at 704-797-4263, or mark.wineka@salisburypost.com.